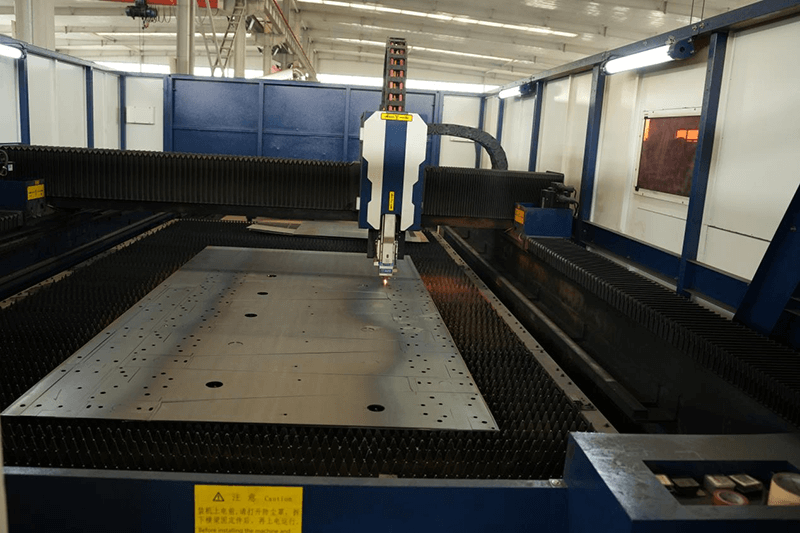

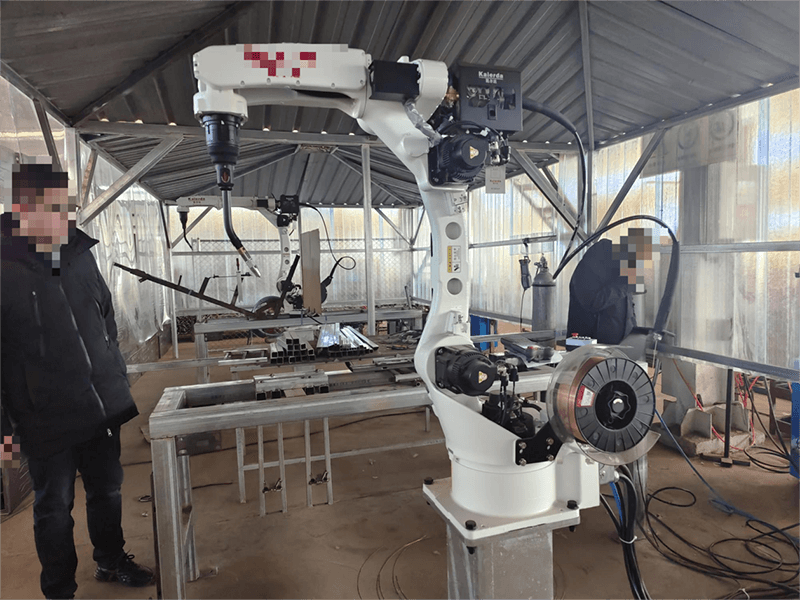

Kutshanje, umzi-mveliso wethu wentsebenziswano uye wazisa ibhetshi yeerobhothi ezikrelekrele ze-welding, iirobhothi ezinjalo ezikrelekrele ziye zasinceda ukuba senze iimveliso ezikumgangatho ongcono kunye nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho.

Inqanaba le-automation kunye nobukrelekrele benkqubo ye-welding ibonakaliswa ikakhulu kwinqanaba lophuhliso lobuchwepheshe berobhothi.Umsebenzisi uhambisa ijoyinti nganye yerobhothi kwinkqubo yolungelelwaniso oluxande okanye lwepolar, uhambisa umzuzu wokuthengisela ecaleni kwendlela ye-welding, urekhoda indawo, isimo sengqondo somzuzu wokuthengisa, iiparamitha ezishukumayo kunye neeparitha zenkqubo kwindlela yomzuzu wokuthengisa, kwaye ivelise iinkqubo eziqhubekayo zokufundisa. yonke imisebenzi.

Olu hlobo irobhothi akanalo impazamo indibano workpiece, deformation thermal kwinkqubo ukuwelda utshintsho bume, kunye nokutshintsha into umsebenzi kufuneka isakhono, ngoko ke, ukuphuhlisa isizukulwana esitsha uneentlobo ngeentlobo zevamvo umsebenzi, ungenza ngokuzenzekelayo trajectory, Isimo sengqondo somzuzu we-welding kunye ne-welding parameters yerobhothi ekrelekrele iya kuba yeyona ndlela yophuhliso.

Uphuhliso lwezixhobo ezitsha luya kuphuhliswa lujolise ekusebenzeni okuphezulu, ukusebenza okuphezulu (kubandakanya ukushisela okuhle) kunye nenzuzo yokusingqongileyo.I-Welding iya kuphuhlisa inkqubo ye-welding engcono, iphuhlise unikezelo lombane olungcono kunye nokuphuhlisa iteknoloji yokulawula ehambelanayo, ukuphucula iqondo lokuzenzekelayo kunye nokwandisa umda wesicelo serobhothi: ukunciphisa izinga le-scrap kunye nesantya sokulungisa, ukunciphisa iindleko ze-welding, ukuphucula imveliso. ukusebenza kakuhle (okufana: ukunciphisa, emva kokufudumala, ukushisa, ukuphepha ukutshisa i-welding, njl.), Ukuphelisa ingcamango "ye-welding ngumqobo wenkqubo yokuvelisa".

Ixesha lokuposa: Jun-18-2024